Environments

- Underwater : Open water, ports, full storages...

- Confined Spaces : Void, ballast & potable water, cargo & storage, tanks...

- High access : Cranes, buildings assets, flares, blades, chimney...

Use cases

- Class inspection

- Flag statutory inspection

- Insurance expertise

- Clear up doubt

- Pre docking preparation

- CAP (Condition Assessment Program)

Assets / Sites

- Vessels

- Wind Farms

- Offshore platforms

- Ports

- Storage sites

Visual Inspection

Visual Inspection

High Access

With the use of drones, it is now possible to inspect structures such as wind turbines, cranes, buildings or other assets with ease, speed and accuracy.

Traditionally, inspecting high areas required scaffolding, rope access or cherry pickers, which are dangerous, costly and/or time-consuming. The use of drones for visual inspection in high areas eliminates these risks. It allows a safer and more efficient inspection process.

Drones can complete an inspection in a matter of hours or even less.

This allows to reduce the downtime of your asset.

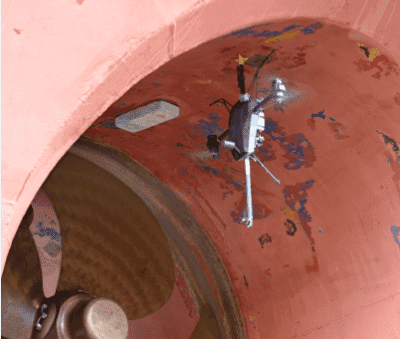

Confined Spaces

Confined spaces are areas which are difficult to access, or hazardous for humans to enter.

Indeed, inspecting these area types with traditional methods caused 10 deaths each year for more than 20 years in the shipping industry. The use of drones for visual inspection in these spaces is a game-changer, as it allows safer, faster and more efficient inspections.

Drones are also more cost-effective than traditional inspection methods. For example, using a cherry picker or scaffolding to access an unclosed space can be expensive and time-consuming, requiring a significant amount of planning and coordination. Drones, on the other hand, can be deployed quickly and easily,

reducing the time and resources needed for an inspection, and of course the downtime of the asset with possible SIMOPS.

Underwater

Thickness Measurement

Thickness Measurement

Visual inspection should, sometimes, be completed by thickness measurement for various assets.

Thanks to our partnerships settled for years with developers, we can now offer this thickness measurement, even at height, with different solutions.

Outdoors or indoors, drones, poles or crawler now allows to reduce means of access.

Overall, using these innovations for thickness measurement offers several benefits, including improved efficiency and safety compared to traditional methods.

Modelization

Modelization

3D modeling using a drone is a process by which a structure, property or object is recreated in a digital 3D format from pictures or LIDAR taken by the drone. This virtual copy of reality is extremely accurate and is used in many sectors.

The process of 3D modeling by drone requires flying close to the area or object to be modeled. The drone is equipped with a high definition camera, which captures multiple images from various perspectives. All images are overlapping to create a detailed representation, allowing the precise calculation of measurements, surfaces and volumes.

After having taken the images, a special software is used to create a 3D model of the subject using a tightly packed dot network. The mesh and texturing of the model are then refined to increase the level of detail and realism. Once these operations are completed, an incredibly realistic and high definition model is produced.

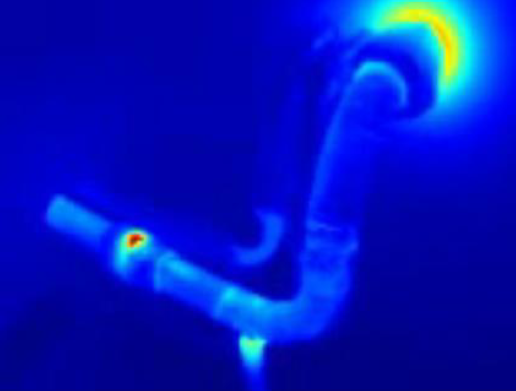

Thermography

Aerial thermography is an infrared imaging process that allows the evaluation of heat emission by an object.

This analysis offers many advantages including the knowledge of assets defects and thermal leaks.